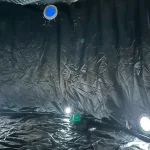

Secondary containment liners are a critical safety measure in industrial and environmental protection systems. Designed to prevent leaks and spills from contaminating surrounding areas, these liners offer a cost-effective solution to comply with environmental regulations and avoid costly cleanups.

The Role of Spill Bunds and Bund Liners

A key component of many secondary containment systems is the spill bund, often reinforced with bund liners. These barriers serve as the first line of defense, capturing hazardous liquids and preventing them from escaping the primary container. Bund liners are professionally installed to ensure maximum protection and long-term durability.

Advantages of Secondary Containment Solutions

Secondary containment liners are available in a wide variety of materials and formats to suit different industrial needs. Whether used for chemical storage, fuel tanks, or wastewater systems, these lining systems help maintain the integrity of your storage tanks and prevent environmental damage.

Key benefits include:

- Leak prevention and containment.

- Compliance with environmental standards.

- Protection against ground contamination.

- Compatibility with secondary containment systems like spill bunds.

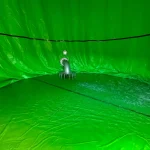

Customised and Cost-Effective Liner Options

High-quality secondary containment solutions can be tailored to your site’s specific requirements. These liners offer excellent chemical resistance, flexibility, and durability. Many suppliers offer a wide range of options to meet both small- and large-scale project demands.

Why Regular Inspections Matter

Even the best liner needs regular checks. Inspections ensure your containment system remains functional, extends its life, and minimizes risks of failure. Maintenance can be scheduled in line with industrial regulations and site-specific needs.

Need Help Choosing the Right Secondary Containment Liner?

Call us today at 1800 907 834 or info@raventanks.com.au to speak with a liner expert and get a free consultation.