Protecting and extending the lifespan of storage tanks is a crucial task for any business handling liquids or chemicals. One of the most effective ways to ensure reliability and safety is by using secondary containment liners.

What Are Secondary Containment Liners?

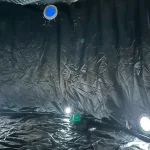

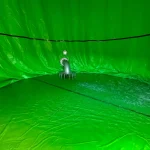

Secondary containment liners are special protective barriers installed inside or outside the primary tank. They act as a shield that prevents hazardous liquids from leaking into the environment and protects the tank material from corrosion, wear, and damage.

Benefits of Using Secondary Containment Liners

- Extends Tank Lifespan: Liners protect the walls from harsh chemicals and weather conditions, slowing down wear and tear.

- Prevents Leaks and Spills: In case the main tank is compromised, the secondary liner holds the liquid, minimizing contamination risks.

- Environmental Safety: Liners help comply with environmental regulations and standards.

- Reduces Repair and Replacement Costs: A protected tank lasts longer, saving money on costly repairs and replacements.

Practical Tips for Choosing and Maintaining Liners

- Choose materials based on the type of liquid and operating conditions: Popular options include PVC, high-density polyethylene (HDPE), and polypropylene.

- Conduct regular inspections and maintenance: Checking liner integrity helps detect and fix issues early.

- Follow manufacturer guidelines for installation and use: Proper installation and care are key to durability.

Key Considerations When Installing Secondary Containment Liners

Before installing secondary containment liners, it’s important to evaluate several factors to ensure optimal performance:

- Compatibility: Verify that the liner material is chemically compatible with the stored liquid to prevent degradation or failure.

- Tank Design: Consider the shape, size, and structure of your tank to select a liner that fits properly and allows easy installation.

- Regulatory Compliance: Ensure the liner meets local and international environmental and safety standards.

- Installation Expertise: Engage experienced professionals to install the liners correctly, preventing common issues like wrinkles, tears, or improper sealing.

- Maintenance Plan: Develop a routine inspection and maintenance schedule to monitor liner condition and address any wear promptly.

By carefully planning and executing the liner installation, you maximize protection and prolong your storage tank’s life effectively.

Conclusion

Secondary containment liners are a smart investment for any tank owner. They provide reliable protection, extend equipment lifespan, and promote environmental safety. Using these liners helps avoid costly accidents and downtime, ensuring stability and peace of mind.

Protect your tanks with Raven Liners – contact us today at 1800 907 834 for expert installation and long-lasting protection!