Architectural tank lining solutions play a crucial role in industries that require durability, safety, and functionality. From custom metal structures to specialized tank components, these solutions provide both aesthetic and structural value. In particular, engineered designs for water and chemical storage systems ensure compliance with strict industry standards while maintaining long-term performance.

Secondary Containment Liners for Safety and Compliance

Secondary containment liners are essential for protecting the environment from hazardous spills and leaks. These liners are commonly used in fuel storage, chemical plants, and water treatment facilities. By installing high-quality secondary containment liners, companies can minimize environmental risks and ensure compliance with regulatory frameworks. Variations, such as flexible geomembrane liners, are designed to provide maximum protection against chemical seepage and corrosion.

Corrosion-Resistant Pond Liners for Longevity

For agricultural, aquaculture, and industrial applications, corrosion-resistant pond liners offer reliable water retention and protection against chemical damage. Unlike traditional liners, high-density polyethylene (HDPE) and other advanced materials ensure long service life even in challenging environments. Corrosion-resistant pond liners are not only cost-effective but also help maintain water quality, making them ideal for fish farming, irrigation, and industrial wastewater management.

Comprehensive Tank Lining Solutions

Tank lining solutions are critical for extending the lifespan of steel, concrete, and fiberglass tanks. Proper lining prevents leaks, corrosion, and contamination, ensuring safe storage of drinking water, chemicals, and fuels. Options such as epoxy coatings, rubber linings, and HDPE liners provide versatility depending on the application. Modern tank lining solutions also support retrofitting, allowing damaged tanks to be restored instead of replaced.

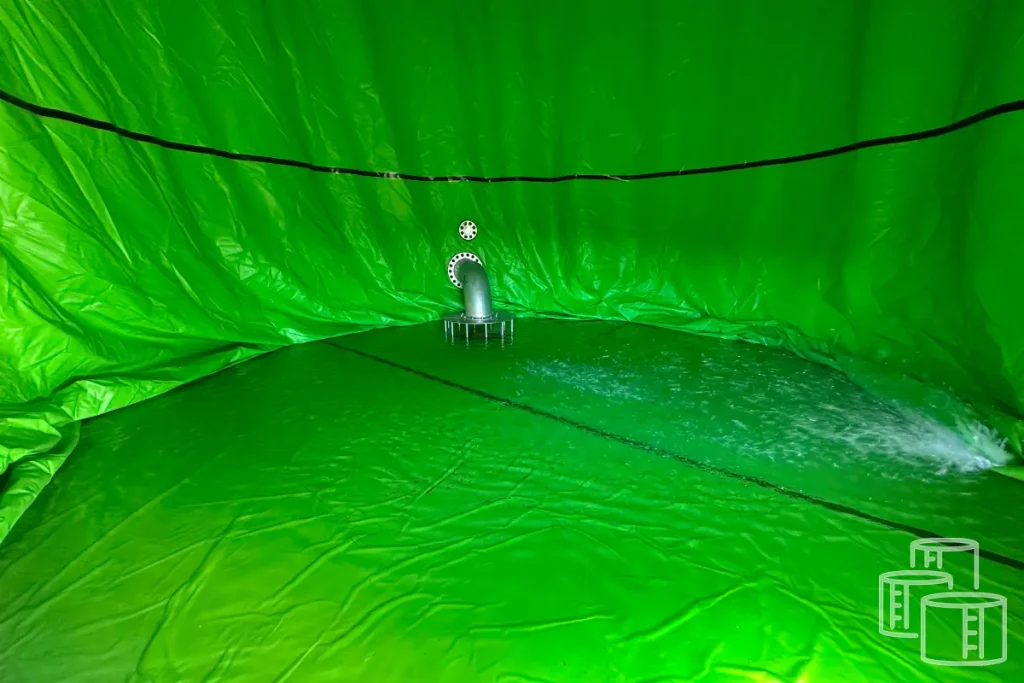

Commercial Tank Liners for Large-Scale Operations

Commercial tank liners are designed to meet the demands of industries such as mining, manufacturing, food processing, and energy. These liners are engineered to handle large volumes of liquids while resisting corrosion and chemical attacks. Custom-fabricated commercial tank liners can be installed in sectional tanks, bolted steel tanks, or concrete reservoirs, offering a cost-effective alternative to full tank replacement.

Expert Installation of Tank Liners

Successful performance of any lining system depends on professional installation. Installation of tank liners requires precision to ensure a seamless fit and prevent leaks. Expert teams use advanced welding and sealing techniques for geomembrane liners, guaranteeing long-term protection. Proper installation of tank liners also ensures compliance with safety regulations and reduces maintenance costs for facility operators.

Conclusion

Architectural fabrication solutions, combined with secondary containment liners, corrosion-resistant pond liners, and specialized tank lining solutions, provide industries with safe, reliable, and cost-efficient storage systems. From commercial tank liners to expert installation of tank liners, these services ensure durability, compliance, and environmental protection across various applications.

Contact our team today at 1800 907 834 to learn more about our architectural fabrication solutions, commercial tank liners, and professional tank lining installation services.